The NECO mixed flow dryer is one of the most efficient dryers on the market, maximizing the test weight of dried grain and lowering your energy bill.

Designed to easily and efficiently condition all types of grain, we can customize a complete grain drying system to suit your needs – supplying the equipment, the install crews, and the service technicians.

The mixed flow drying process preserves grain quality, while even cooling & heating provides kernel to kernel consistency.

The NECO dryer has unequalled energy efficiency, saving up to 20-30% on fuel costs compared to conventional screen dryers.

No screens to clean or unplug, maintaining airflow throughout the drying season and making it suitable for drying all grains without the risk of plugging.

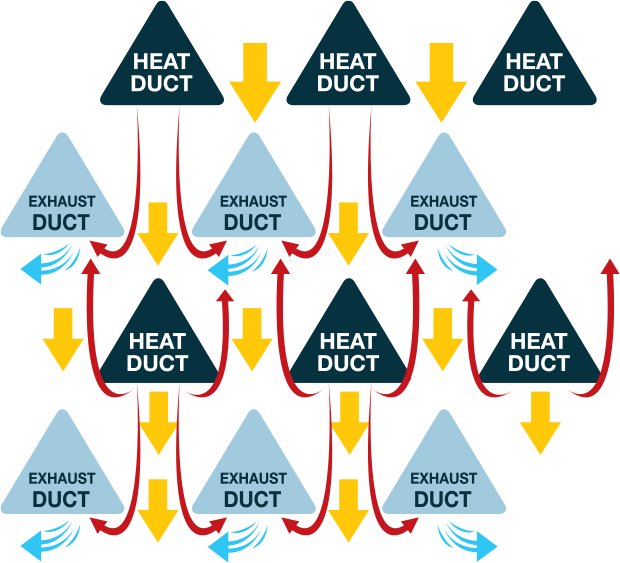

Heated air travels through the column of moving grain via the internal heat ducts, making the drying process more efficient as well as conserving the quality of grain. The heated air then exits through the outer exhaust ducts.

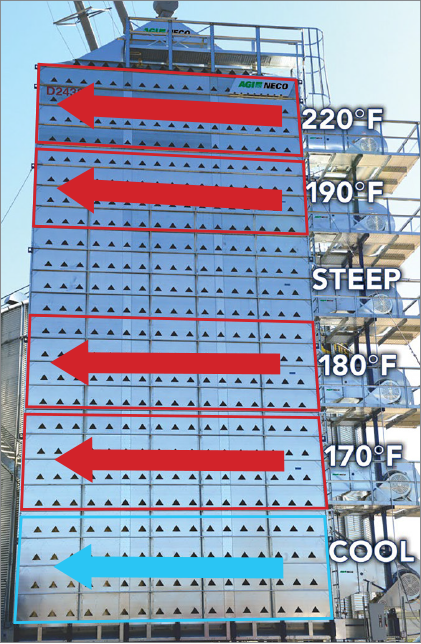

Allows dryer to run in full heat or heat and cool modes on single burner dryers.

For multiple burner dryers:

NECO dryers use COMMANDER CONTROL with a DRYERMASTER moisture control system.

Flaman Grain Systems offers additional options to complete your grain handling system:

You can also package your NECO grain dryer with Galvanized Hopper Combo bins, Galvanized Flat Bottom bins, or Smoothwall bins.

Contact us for a free site plan and to see how a Neco Grain Dryer package can be part of your handling solution.

Coming Soon